Original content by: Leather International

The leather industry, a cornerstone of global manufacturing, faces numerous challenges from extreme weather events. Climate change has intensified the frequency and severity of these events, leading to disruptions in supply chains, production processes, and market dynamics. This article explores the impacts of extreme weather on the leather industry, strategies for mitigation, and resilience-building measures that industry stakeholders can adopt.

Understanding extreme weather events and their economic impact

Definition and Scope

Extreme weather events include hurricanes, floods, droughts, heatwaves, and storms, which are becoming increasingly common due to climate change. These events can cause widespread devastation, affecting infrastructure, agriculture, and economies globally. Industries dependent on stable environmental conditions, like leather, are particularly vulnerable.

Economic Consequences

The economic impact of extreme weather is profound. Direct consequences include the destruction of infrastructure and loss of livestock, while indirect consequences manifest as supply chain disruptions, increased costs, and shifts in market demand. For the leather industry, these impacts can translate into significant operational challenges and financial losses.

The leather industry: an overview

Global Market Dynamics

The leather industry produces a range of products, including footwear, garments, accessories, and automotive upholstery. Key players include countries like Italy, India, Brazil, and China. According to Grand View Research, the global leather goods market was valued at approximately USD 407.92 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028.

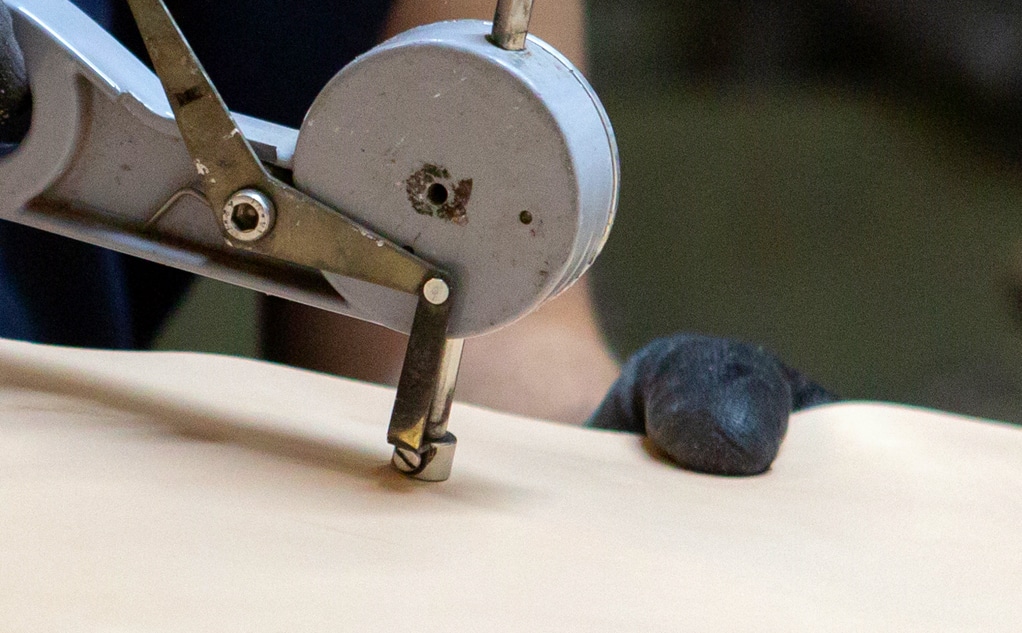

Supply Chain Structure

The leather supply chain involves several stages: sourcing raw hides and skins, tanning, and manufacturing finished goods. The initial stages depend heavily on livestock farming, which is highly susceptible to weather conditions. Subsequent stages, such as tanning and manufacturing, also face challenges from extreme weather events.

Impact of extreme weather on the leather industry

Disruption of Raw Material Supply

Extreme weather events can severely disrupt the supply of raw materials. Livestock farming, the primary source of hides and skins, is particularly vulnerable. Droughts can reduce water and food availability for livestock, while floods and storms can lead to livestock loss and damaged infrastructure.

Case Study: Australian Droughts

Australia, a significant exporter of raw hides, has experienced severe droughts in recent years. These droughts have led to reduced livestock numbers and lower quality hides, impacting leather manufacturers dependent on Australian raw materials. The scarcity of hides has driven up prices and forced manufacturers to seek alternative suppliers.

Transportation and Logistical Challenges

Extreme weather often damages critical infrastructure, including roads, railways, and ports, leading to transportation delays and increased costs. For the leather industry, timely delivery of perishable raw hides is crucial. Delays can result in spoilage and financial losses.

Case Study: Hurricane Harvey

Hurricane Harvey, which hit the United States in 2017, caused extensive flooding and infrastructure damage in Texas, a key logistics hub. The disruption affected the transportation of hides and leather goods, leading to significant delays and increased costs for manufacturers relying on these supply routes.

Impact on Labour and Production Facilities

Extreme weather events can also disrupt labour availability and damage production facilities. Floods, hurricanes, and other severe weather conditions can displace workers, damage factories, and halt production. The leather industry, which relies on skilled labour and specialised equipment, can face prolonged downtimes and increased recovery costs.

Economic Losses and Market Fluctuations

The financial impact of extreme weather can be substantial, with increased operational costs and fluctuating market demand. Consumers’ purchasing behaviour often changes in response to economic instability caused by weather-related disruptions, affecting demand for luxury leather goods.

Case Study: Floods in Bangladesh

Bangladesh, a significant player in the global leather industry, has faced recurrent flooding, affecting tanneries and production facilities. The floods have led to production stoppages, increased costs for damage repair, and disrupted supply chains, impacting the global leather market.

Resilience and adaptation strategies

Diversification of Supply Chains

To mitigate the risks associated with extreme weather, leather companies are increasingly diversifying their supply chains. By sourcing raw materials from multiple regions, companies can reduce dependency on any single area affected by weather disruptions, ensuring a more stable supply.

Investment in Technology and Innovation

Technological advancements can help the leather industry adapt to extreme weather. Innovations in synthetic leather and alternative materials provide options that are less dependent on traditional supply chains. Additionally, advancements in logistics technology can optimise transportation routes and improve supply chain visibility, helping companies navigate complex environments.

Case Study: Sustainable Leather Alternatives

Companies like Piñatex and Modern Meadow are developing sustainable leather alternatives using materials like pineapple fibres and lab-grown collagen. These innovations reduce reliance on traditional raw hides and offer resilience against climate-induced supply chain disruptions.

Strategic Stockpiling and Inventory Management

Maintaining strategic stockpiles of critical raw materials and chemicals can help leather manufacturers buffer against short-term supply disruptions. Effective inventory management ensures continued production during periods of instability, reducing the financial impact of extreme weather events.

Geographic Diversification of Manufacturing

Establishing production facilities in multiple regions can mitigate the risks associated with extreme weather. By spreading manufacturing operations across different areas, companies can reduce their exposure to any single location’s weather-related disruptions, ensuring operational continuity.

Collaboration and Industry Initiatives

Collaborating with industry stakeholders and participating in initiatives focused on sustainability and climate resilience can enhance the leather industry’s preparedness for extreme weather. Industry-wide efforts to adopt best practices and share knowledge can lead to more robust and adaptable supply chains.

Case Study: Leather Working Group (LWG)

The Leather Working Group (LWG) is an example of an industry initiative promoting sustainable practices. By setting environmental standards and encouraging collaboration, LWG helps leather manufacturers improve their resilience to environmental challenges, including extreme weather events.

Policy and regulatory frameworks

Government Support and Incentives

Governments can play a crucial role in supporting the leather industry’s resilience to extreme weather. Policies and incentives promoting sustainable farming, disaster preparedness, and infrastructure development can mitigate the impacts of weather-related disruptions.

Case Study: EU Climate Policies

The European Union has implemented various climate policies and funding programmes to support industries affected by climate change. These initiatives provide financial support and resources for adopting sustainable practices and enhancing resilience to extreme weather.

International Trade Agreements

Engaging with international trade agreements can provide a framework for navigating trade barriers and disruptions caused by extreme weather. Agreements like the European Union’s Generalised Scheme of Preferences (GSP) offer reduced tariffs for exports from developing countries, helping leather manufacturers access new markets and maintain competitiveness.

Building a resilient future

Embracing Sustainability

Sustainability is key to building resilience in the leather industry. By adopting sustainable practices across the supply chain, from raw material sourcing to manufacturing, companies can reduce their environmental impact and enhance their ability to withstand extreme weather events.

Investing in Research and Development

Continued investment in research and development (R&D) is crucial for the leather industry’s long-term resilience. R&D can lead to innovations in materials, processes, and technologies that improve the industry’s adaptability to changing weather patterns and environmental conditions.

Case Study: Circular Economy Initiatives

Circular economy initiatives, such as recycling and upcycling leather waste, are gaining traction in the industry. These practices reduce reliance on raw materials and minimise waste, contributing to sustainability and resilience against supply chain disruptions.

Enhancing Disaster Preparedness

Developing robust disaster preparedness plans can help leather manufacturers respond effectively to extreme weather events. These plans should include risk assessments, emergency response protocols, and recovery strategies to minimise the impact of weather-related disruptions.

Case Study: Business Continuity Planning

Companies like Nike and Adidas have implemented comprehensive business continuity plans to address potential disruptions, including extreme weather. These plans ensure that critical operations can continue, reducing the financial and operational impact of such events.

Conclusion: adapting to a changing climate

Extreme weather events pose significant challenges to the leather industry, from disrupting supply chains to increasing operational costs. However, the industry has shown resilience through diversification, innovation, and collaboration. By embracing sustainability, investing in technology, and enhancing disaster preparedness, the leather industry can navigate the challenges posed by extreme weather and build a more resilient future.

As climate change continues to impact global weather patterns, the leather industry must remain agile and proactive. By anticipating potential disruptions and implementing robust strategies, leather manufacturers can safeguard their operations and continue to thrive in an increasingly volatile world. Through concerted efforts to enhance supply chain resilience, adopt sustainable practices, and leverage technological advancements, the leather industry can build a strong foundation capable of withstanding future extreme weather events.

You can access the original article HERE