Content posted by: LEATHER CLUSTER BARCELONA.

On 17 June, Leather Cluster Barcelona took part in the first day of the ‘Sustainable Experiences’ cycle, at the Espai Guasch in Capellades (Barcelona).

The ‘Sustainable Experiences’ are born of the concern for the environment and sustainability. It is an integrative and open project that wants to become a space for reflection and debate to raise awareness and promote actions and projects of sustainability.

In line with the demands of society, ‘Sustainable Experiences’ want to increase environmental and ecological awareness, giving voice and amplifying the message of those practices that directly and positively affect the environment: sustainable business projects, initiatives for contribute to caring for nature or actions to address ecological concerns around consumption.

This first meeting, which brought together more than 40 people, discussed sustainability and zero waste, and had the interventions of featured speakers such as Jordi Vidal, executive director of Leather Cluster Barcelona, who presented different examples of transformation of waste in resources in which the cluster is working.

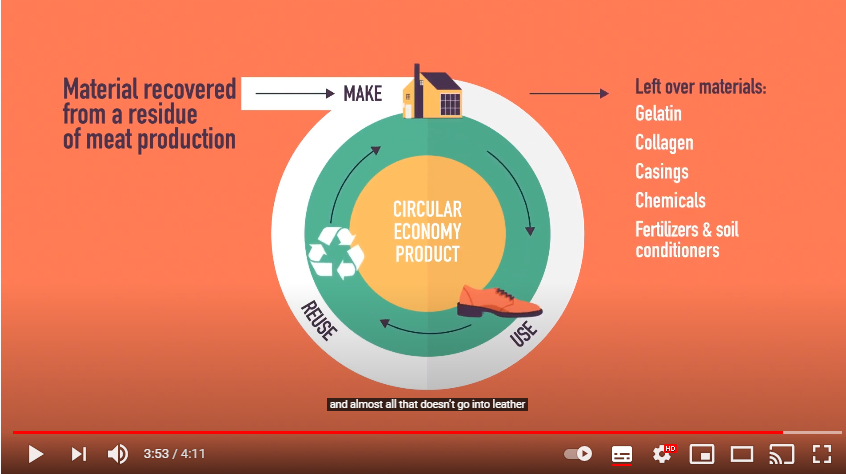

During the guest speech, it was emphasized that we are in a time of paradigm shift in which a positive view is needed: the rejections of one sector can be the raw material of another. The waste of a production process can have a second useful life, being valued in raw materials by other industries or processes.

You can read the original content HERE.